If you want to build a wooden security screen, all you need to do is build the frame, add a fiberglass screen using a staple gun, and finish it with screen mold.

Contrary to what you might think, you don’t need to call a carpenter to build a security screen for your window. Using a few cheap tools, you can build one yourself in less time than it would take to call in a professional.

I will go into more detail below.

Things you will need for this job

- Aluminum Screen Frame Kit

- Rubber Spline (might be included in the kit)

- Fiberglass Sheet (might be included in the kit)

- Measuring Tape

- Mitre Box

- Spline Roller

- Hacksaw

- Pocket Paper Cutter

You might be asking, “Wait, Aluminum Screen Frame Kit? What if I want to build a wooden frame myself?” If this is the case and you desire you build the frame yourself, the only materials other than those needed to build a wooden frame are;

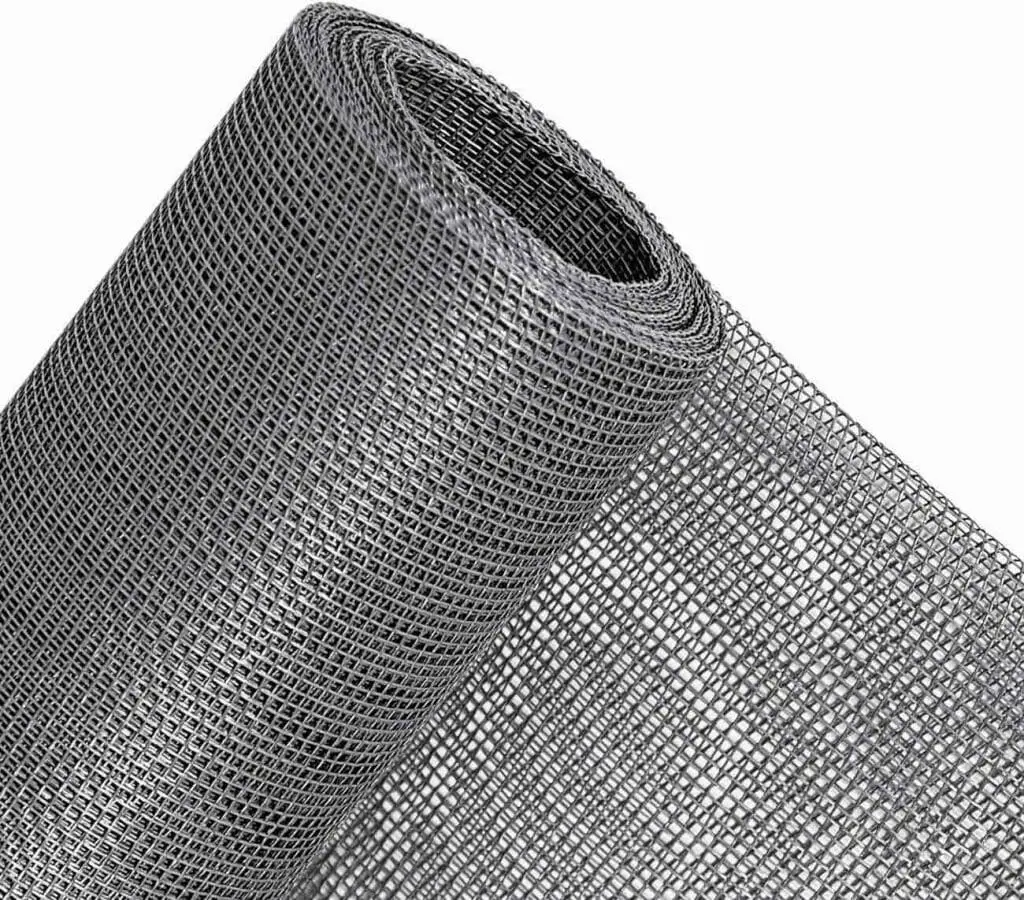

- Fibreglass Sheet

- Staple Gun

- Screen Mold

- A pair of scissors

We have covered whether you use the aluminum kit or make a wooden frame. First, we go into making a DIY security screen using the aluminum kit, and then we discuss the process of making a wooden DIY Security Screen.

Building a Aluminum DIY Security Screen

The materials used in the screen will cost you around $16, making it quite inexpensive. If you do not have the required tools buying all of these, including the screen supplies, will cost you about $37.

The frame kit can make a 48-inch by 48-inch frame, but you can resize it to the size of your window using a hacksaw.

In the following steps, I’ll show you how to build a window security screen frame and how to place the fiberglass mesh. (1)

Take Starter Measurements

The first step is to get accurate measurements of what your security screen should be. If you have a security screen that you wish to replace, you can measure its dimensions to build your frame.

If you don’t have an old security screen, here’s what you must do. You have to measure the dimensions of your window and subtract 1.5 inches from the height and width measurements. This is to accommodate the width of the frame contours.

Cutting frame to appropriate length

Once you have measured the width and height of your window and have accommodated the width of the frame contours, you can use the miter box and the hacksaw to cut the aluminum frame to the appropriate length.

Measuring and cutting the frame accurately is important since you might be building a security frame instead of buying one to have a frame that matches your window. It pays a lot to be a little more careful with measurements and cutting.

Join the Sides Together

Once the sides of the frame are cut to the appropriate length, you are ready to join the sides using the frame corners.

Before you join the sides together, ensure a recess in the frame for the rubber spline to go. The recess should be facing up toward you for all four sides.

It is important to get these steps right to avoid errors and redos and save time.

In these three steps, we focused on building the frame. Now we are going to add the fiberglass.

Add Fiberglass Screen

Once the frame is ready, you can add the fiberglass screen. I found it best to divide this step into several sub-steps. Here is how you can add the fiberglass screen to the frame.

- Lay the security screen frame on a flat surface such that the recess on all the sides is facing up towards you. If only some of them are facing you, please refer to step 3: “Join the Sides Together.”

- Roll out some of the fiberglass screens on top of the frame. The fiberglass screen should be a few inches wider than the frame on all four sides.

- Place the rubber spleen on the top of the fiberglass screen and the frame directly above where the recess is.

- Use the spline tool (that looks like a pizza cutter) to insert the rubber spline into the recess. This will fix the fiberglass screen to the frame. (Admittedly, this part is really fun to do)

- Cut the excess fiberglass screen using the pocket paper cutter. The best way to do this is to hold the cutter at a 45-degree angle to the frame and cut the fiberglass mesh.

- Push in the rubber spline with the spline tool one more time to ensure the screen is tightly fixed.

Once you buy the spline tool and learn how to do this, I’m sure you’d want to replace all the old fiberglass screens in your window frames.

Wooden DIY Security Screen

Assuming you have woodworking skills, making a wooden security door should be a piece of cake. Making your wooden security screen also allows you to vary the sturdiness of your security screen by choosing different widths and types of wood and adding a different number of screen molds.

Here are the steps to making a wooden security screen.

Make the Frame

We start with making the wooden frame. Measure the dimensions of your window and make a frame of the appropriate size. The frame could be made of wood beams of any thickness, depending on your preferences.

Add the Fiberglass Screen

Once the frame is ready, you can add the fiberglass screen. Layout the fiberglass sheet on top of the frame and use the stapler gun to fix the fiberglass screen in place. Make sure you keep pulling the fiberglass screen so it stays tight.

Place staples one inch from each other around the frame and then connect the fiberglass screen to the frame. Now, use scissors to cut the fiberglass screen on the sides, only leaving enough to be hidden with the screen mold.

Nail-in the Screen Mold

Once the fiberglass screen is tightly in place, you can place screen molds on top of the staplers. Apply PVA glue all around the frame on top of the staples. Now use nails to place the screen molds on top of the glue, hiding the staples and the loose fiberglass screen. Once the glue dries, your security screen is ready.

Wrapping Up

You can easily build a security screen at home that is cost-effective and does not take a lot of time.

There are two types of security screens you can build: aluminum security screens and wooden security screens. An aluminum security screen takes less time, is easier to build, and may cost less than a wooden security screen, but a wooden security screen may be stronger.

Whichever one you choose to build, if you follow the instructions provided here, you will have built a professional-quality security screen, spending less time and less money.

References

(1) fiberglass – https://cen.acs.org/materials/inorganic-chemistry/s-fiberglass-does-delicate-material/96/i38